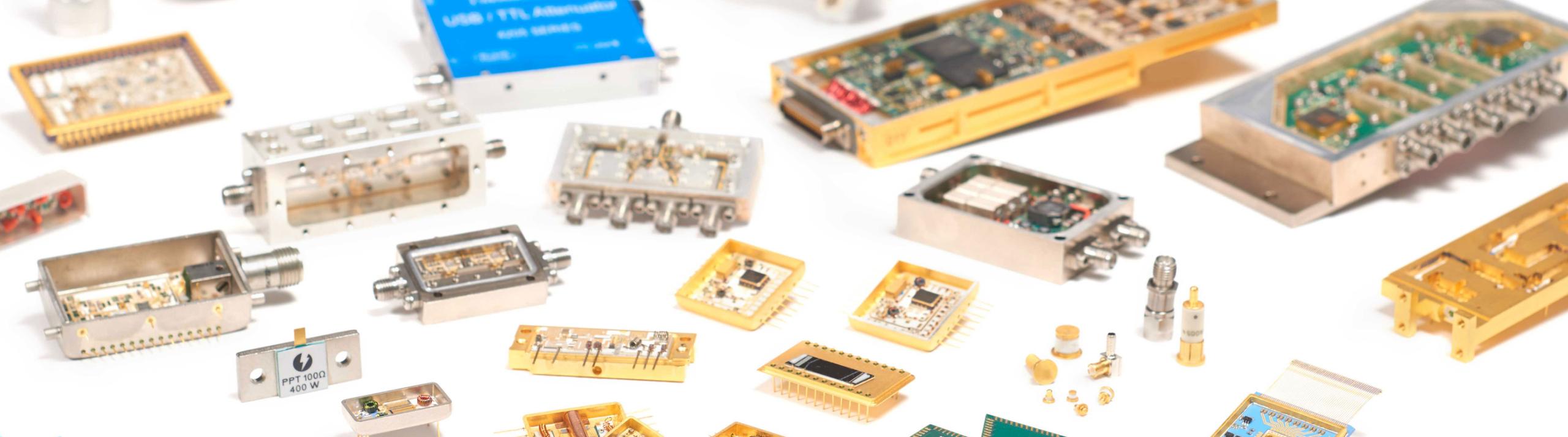

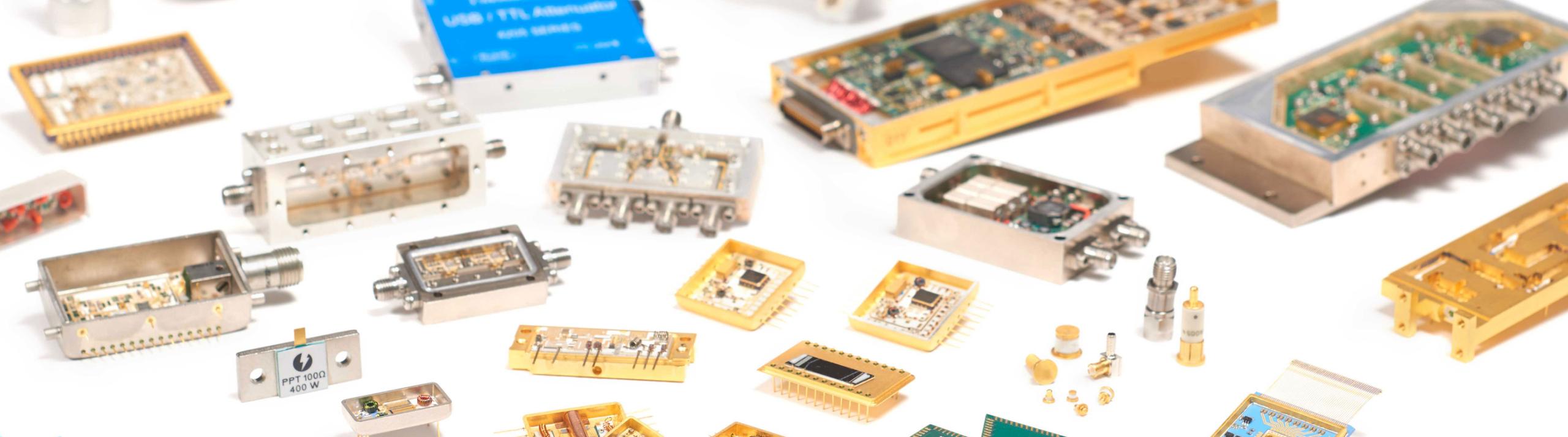

Products

Control the Spectrum

Protect your systems from wideband spurious signals from transients, power, & transmission noise

Selectively filter incoming RF to pass through precisely conditioned signals for downstream processing

Tune the power output for gain, bandwidth, efficiency, linearity, input/output impedance matching

Apply our multidisciplinary approach to design and manufacture complex, high performance devices and modules for signal processing and conversion